About JKL Technology

As an industrial automation connector manufacturer, JKL Technology specializes in the design, development, and production of connectors and interconnect solutions tailored for the needs of the industrial automation sector. JKL Technology as a manufacturer plays a crucial role in supporting various industries, including manufacturing, robotics, automotive, aerospace, and more, by providing essential components that enable seamless communication and power transmission within automated systems.

Here’s what we do as an industrial automation connector manufacturer:

Product Development: JKL invests in R&D to create innovative connector solutions that meet the specific requirements of automation systems. This includes designing connectors that can handle high-speed data transfer, power distribution, signal integrity, and harsh environmental conditions.

Customization: We offer customization services to provide connectors that precisely match the unique needs of our clients’ automation setups. Customized connectors ensure optimal performance and compatibility within a particular application.

Quality Assurance: Manufacturers adhere to stringent quality control processes to produce connectors that are durable, reliable, and capable of withstanding the rigors of industrial environments. This includes testing for factors like temperature resistance, vibration tolerance, and ingress protection.

Standard Compliance: We ensure that our connectors comply with industry standards and regulations to guarantee interoperability and safety.

Innovation: Staying at the forefront of technological advancements, we continually innovate to offer connectors that support the latest automation technologies, such as Industry 4.0, the Industrial Internet of Things (IIoT), and smart manufacturing.

Technical Support: We provide technical expertise and support to help customers select the right connectors for their applications. This includes offering guidance on connector types, pin configurations, and compatibility with automation equipment.

Sustainability: Many connector manufacturers prioritize sustainability by implementing eco-friendly manufacturing processes and materials. This aligns with the growing emphasis on environmentally responsible practices in modern industries.

Our History and Milestones

2004 JKL established in Taiwan in April

2005 Participating in Hanover Exhibition in Germany.

2006 JKL started business in UK and set up an agency for new market promotion on waterproof series of products. In the meantime, JKL also became supply-chain of Lumberg in Netherlands, Germany, United Kingdom, Singapore, and Mainland China.

2007 Set up a new market in Malaysia and got a GPS tracking system project for sea container with M12 waterproof cabling.

2008 Achieve a new E-bike of waterproof lighting project.

2008 Become a member of DUNS and become the supply-chain of car industry with listed No. : 79421 for Volvo.

2009 Open a new market in Italy.

2010 Open a market in Turkey and Poland and got Ethernet project from Radiall.

2011 Get a new project for household water heating system from Quooker.

2012 Become a supply-chain for Yokogawa on his testing equipments with M9 waterproof connector & cabling.

2013 Open a new market in Russia and got a new motor helmet GPS cabling system project from Nolan group, Italy.

2014 Set up an agency in Korea on promoting our water-tight series of products.

2015 Cooperation with Telegartner in United kingdom for Networking products.

2015 JKL got a certificate of ISO 9001:2008 by DAS in July.

2016 JKL got a certificate of IOS 9001:2015 by DAKKS from Germany in September.

2016 JKL got a computerized system project from Belgium.

2017 JKL got Ethernet project from Radiall (Shanghai).

2017 JKL got a new Networking project from the USA.

2018 JKL got Ethernet project from Radiall in India.

2018 JKL got a new railway transportation project with M12 waterproof connector in India.

2019 Become members of TUV Rheinland.

2019 Developing Networking waterproof series of products for market demands.

2020 JKL got a medical cabling project from the USA.

2021 Open a market in Slovakia and got a sensor testing equipment cabling system with our M9 waterproof connector, adaptor & panel mount.

2022 Update certificate ISO 9001:2015 by DAKKS.

2023 Developing the whole networking waterproof series of products with Metal & Plastics shell for different industries demands, such as RJ45 & USB type-C panel mounting, etc…

2024 Promoting our CAT. 6 A high performance Ethernet series of products, especially with full shielded and toolless-type to Europe markets.

2025 Update D&B certificate, listed No. : 656444341 and got the Germany GHMT certificate for whole CAT. 6a Ethernet high-performance series of products such as plug, jack, keystone, adapter and inline coupler.

2025 Update ISO 9001:2025 in September.

2025 Get a new project for USB type-C waterproof project.

2025 JKL becomes an agency of PLUS ENERGY MACHINERY CORP. & DING SHUNG MACHINERY CO., LTD. for promoting on Packaging machinery in African countries.

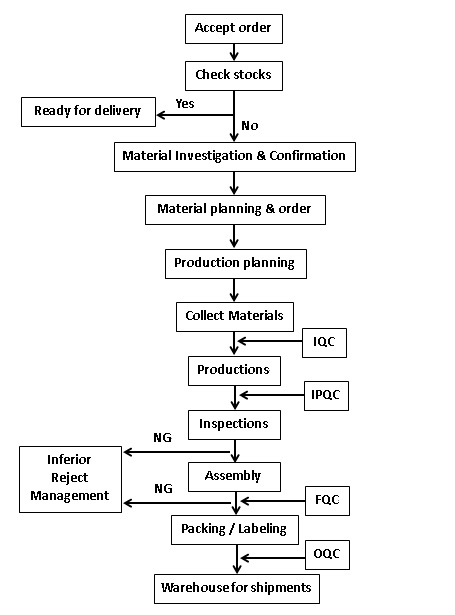

Our Manufacturing Production Flow Chart

Creating a Manufacturing Production Flow Chart for automation connectors involves breaking down the manufacturing process into a series of steps or stages, each of which represents a key activity in the production of connectors. Here’s a generalized overview of the process:

-

Materials Procurement

-

Component Manufacturing

-

Quality Control (Component Level)

-

Assembly

-

Quality Control (Assembly Level)

-

Electrical and Mechanical Testing

-

Coating and Finishing

-

Packaging

-

Quality Control (Final Inspection)

-

Storage and Distribution

-

Documentation and Record Keeping

-

Continuous Improvement

-

Compliance and Certification

-

Customer Feedback and Support

Our Manufacturing Facilities

- Injection molding machine

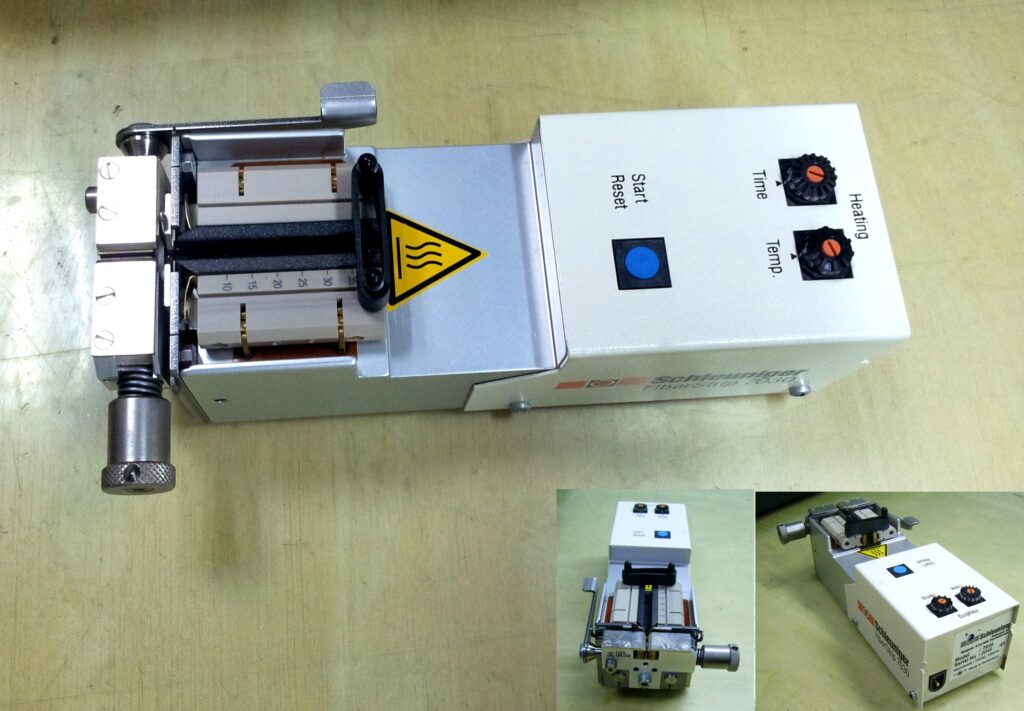

- Solder machine

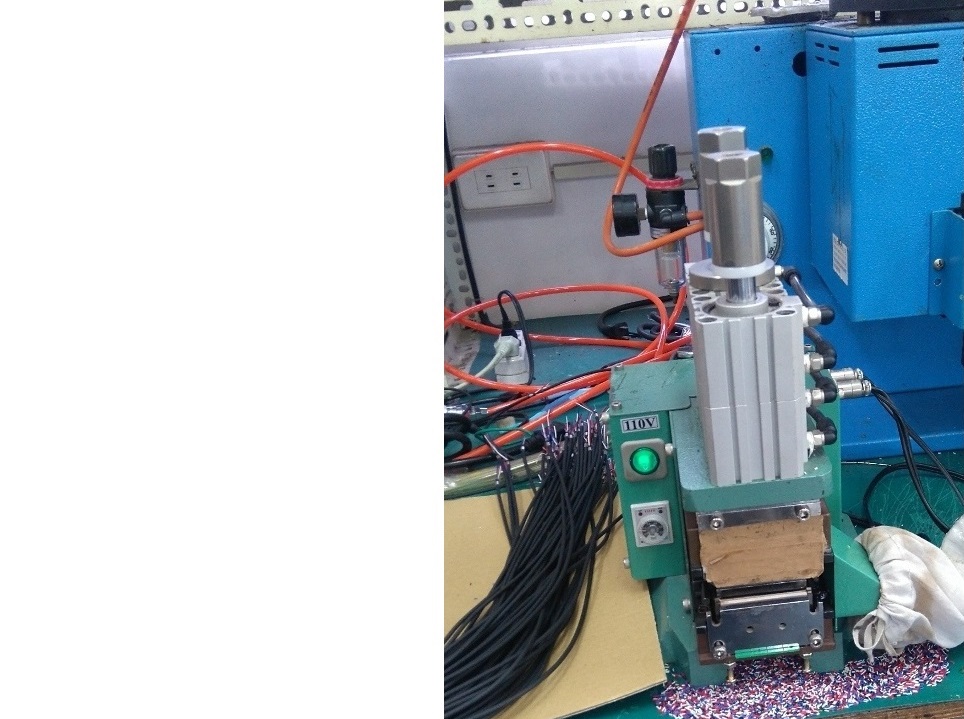

- Crimping machine

- Pad printing machine

- Sonic welding machine

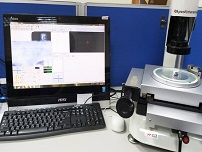

- Cable tester

- Hi-Pot tester

- HP analizer

- Fluke 4300

- Salt spray tester

- Auto wire strip & cut machine

- Air wire stripping machine

- Auto termination machine

- Terminal depth gauge

- High-temperature test device

- Low-temperature test device

- Insert & withdrawal test device

- Low-pressure molding machine

Long-term Relationships with Our Customers

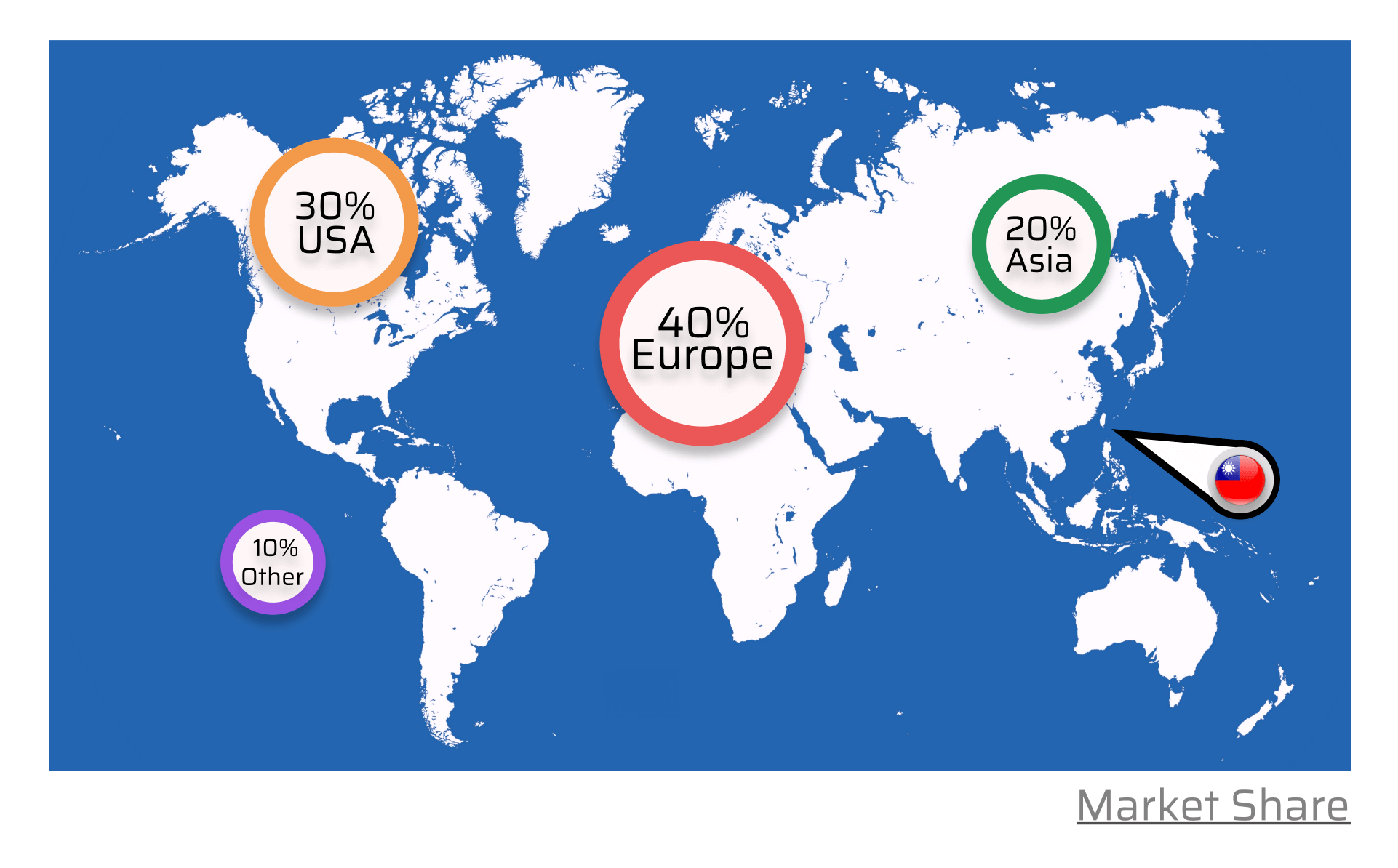

Our cooperation with international companies has been more than a decade, we focus our market mainly in Europe. We strive to expand our business to any potential markets. Meanwhile, we believe in keeping customers satisfied by providing ideal solutions for our customized projects is our key to long-term business.

Our Office and Factory Facilities

Product Ranges

- Audio & Video connectors

- Data transmission connectors

- Power supply connectors

- RF Coaxial connectors

- Test & Measure connectors

- Automotive connectors

- Industrial connectors

- Automation connectors

- Medical equipments connectors

- MIL-DTL-5015 connectors/ Military power connectors

ISO 9001:2015 Certificates and Company Registration license